Chapter 1. Wood and water

Water in the tree

Sapwood and hearthwood

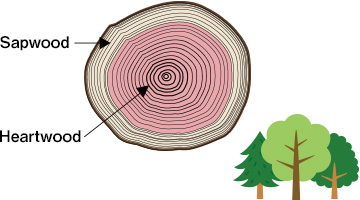

The stem of the tree that we use for lumbering has the role of sending water from the roots to the leaves (water conduct action), so the stem is full of water. Surprisingly, however, it is not the entire stem that passes water, but only the outer part of the stem. the outer part is called sapwood (white portion). Therefore, the sapwood is generally high in moisture, and the heartwood (red portion) is low in moisture (see Table 1).

In addition, in terms of the leaf-drying of logs, you can expect lowering water contents only in the sapwood where water is conducting (running) but not much in the core, which is hearth wood area.

High moisture content in the hearthwood

Table 1.softwood average moisture contents in green wood

| Tree species | Sapwood(%) | Heartwood(%) |

|---|---|---|

| Japanese cypress | 153.3 | 33.5 |

| Thuja standisli carr | 186.0 | 56.2 |

| Japanese red pine | 147.3 | 33.7 |

| Japanese cedar | 148.0 | 113.1 |

| Yezo spruce | 169.1 | 40.6 |

| Todo fir | 211.9 | 76.1 |

| sawara | 154.5 | 38.3 |

There are some species of trees in the world where there is a lot of moisture in the heart of the trees that have not been passed through.

As Table 1 shows, the representative is cedar. To complicate matters, moisture contents percentage in heartwood of ceder differs greatly among individual ceders. This makes drying of cedar wood even more difficult.

| POINT 1 | Generally, in case of green wood, the sapwood contains much water and the heartwood has little moisture. |

| POINT 2 | Some spieces like ceder contain moisture in heartwood area. |

Water in the wood

Cell walls and lumens

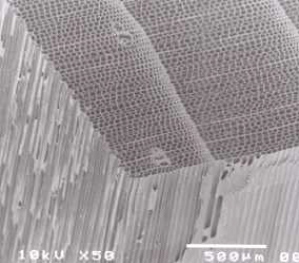

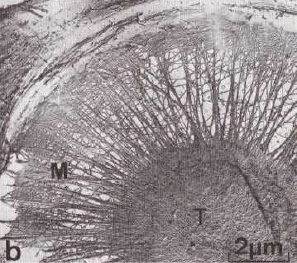

Microphotograph of wood (pine)

Microphotograph of wood (pine)Wood consists of elongated, pipe-like cells running up and down, and they are tightly packed (see photo). As you can see in the picture, the cell is empty. In fact, surprisingly, most cells in wood are already dead, and the contents are gone. The part of the cavity called the inner lumenis, and the wall surrounding the inner lumenis called the cell wall.

Free and bound water

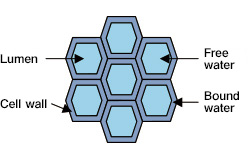

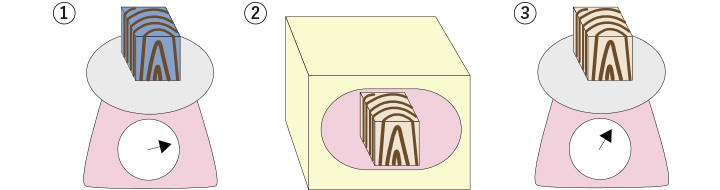

Image of cell cross section

Image of cell cross sectionIn raw wood, there is free water in the lumen of each cell and bound water in the cell wall.

Water passing through the stem moves through the inner lumen, and this water is called free water because it is the same as normal liquid water. There is also water that has entered the small gaps in the cell wall, and these are called bound water because they are in a molecular form and hold hands with the wood component. In other words, wood contains two different states of water: free water and bound water.

| POINT 3 | There are two types of water in wood: free water and bound water. |

| POINT 4 | Free water is running in the inner lumen and bound water is in the cell wall. |

Moisture control valve: PIT

Pit

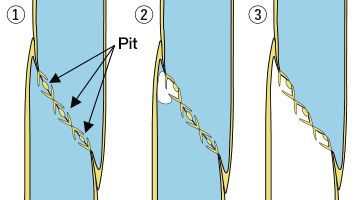

As water moves between cells, it passes through tiny pores called pits that exist innumerably in the cell wall. This wall hole is not just a hole but has a valve called pit membrane that controls the flow of water (see figure).

Under a microscope, this pit membrane is made up of a mesh filter (margo) and a bulging lid (torus) (see photo).

Closed pit of hearthwood

Microphotograph of cell with pits

Microphotograph of cell with pitsThe sapwood valve is relatively free to move, but the heartwood valve is closed and glued after the water has been expelled to prevent water from passing through (heart-forming phenomenon). However, in tree species such as cedar, water suddenly accumulates in the cells of heartwood. The problem here is that the water in the heartwood is trapped inside the cells. Therefore, the movement of water in the heartwood is poor and it takes longer to dry than the sapwood.

| POINT 5 | The pit of sapwood has a role of valve to control water flow. |

| POINT 6 | The pit of heatwood is closed and water is trapped. |

How to express the moisture content of wood

Water content on a dry basis

The water content of wood can exceed 100%. Then you might think that the water is overflowing. The water content of wood is calculated by a method called dry basis. It is not simply a wet basis that indicates the rate of water content. With the dry basis, the weight of water content is shown relative to the weight of completely dry wood (total dry weight). Therefore, more than 100% can happen.

for example,

Wood containing the same amount of water as the total dry weight = 100% water content

Wood containing twice the total dry weight of water = 200% water content

Wood containing half the total dry weight of water = 50% water content

Total dry moisture content

There are various methods for measuring moisture, such as dry method, electric resistance moisture meter, and high-frequency moisture meter. The dry method is a method that can accurately measure the water content. However, for large material, the test pieice needs to be cut from large material for dry method. so material is destroyed. This method is used as a sampling inspection for quality control at the manufacturing site.

① Cut small piece out from material to test and measure it's weight immidiately.

② Put the test piece in an electric oven at 105℃ and let it dry completely until the weight does not change (1-2 days).

③ Measure the weight (total dry weight) of the completely dried piece. Culculate the moisture content.

| POINT 7 | The moisture content of wood can exceed 100% on a dry basis. Moisture content of wood = weight of moisture in wood ÷ total dry weight × 100 =(weight of wood in a certain moisture state-total dry weight)/ Total dry weight x 100 |

Moisture content and moisture condition

Fiber saturation point

In all woods, the presence of water is largely different with a water content of 30% as the boundary. This water content is called the fiber saturation point, and the cell wall is filled with bound water. When the water content exceeds 30%, water (free water) also exists in the lumen of cells. Conversely, when it reaches 30% or less, bound water in the cell wall decreases. The cell wall itself becomes increasingly thinner as the bound water decreases. As a result, lumber, an aggregate of cell walls, gradually shrinks. In other words, the shrinkage associated with the drying of wood is a phenomenon that occurs at or below the fiber saturation point (water content 30%). In addition, at or below the fiber saturation point, various properties such as strength change significantly as the water content changes.

Schematic diagram of moisture state in wood

| Green Wood (30% or more) | Fiber saturation point | Equilibrium water content (about 15%) | ||

|---|---|---|---|---|

|

|

|

|

|

| Bonded water | Saturation | Saturation | About half | No |

| Free water | yes | just a little | No | No |

| Shrinkage | No | No | 1.0~4.5% | 2.0~9.5% |

Equilibrium moisture content

When wood is placed in an environment with a certain temperature and humidity, the wood will eventually have a moisture content balanced with that environment. This water content is called the equilibrium water content. Although it varies depending on the season and region, it is said that the average equilibrium water content in Japan outdoors is about 15%. Also, the equilibrium water content in the air-conditioned room will be about 10-12%.

| POINT 8 | About 30% moisture content is called fiber saturation point. |

| POINT 9 | At or above the fiber saturation point, both free water and bound water are present. |

| POINT10 | At or below the fiber saturation point, only bound water exsists and the wood shrinks. |

| POINT11 | The moisture content balanced with the environment is called the equilibrium moisture content. |

pit between upper cell and lower cell

Role of pit

① The valve (pit membrane) in the center of the pit is in the neutral position and water flows upward freely.

② A bubble is created in the lower cell lumen, and the valve of one pit closes.

③ When air bubbles expand, all valves close to prevent water backflow.